Precision Coatings, Inc. offers several CARBIDE coatings applied by HVOF OR Plasma Spray.

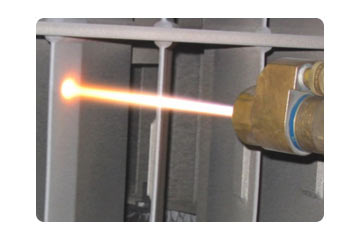

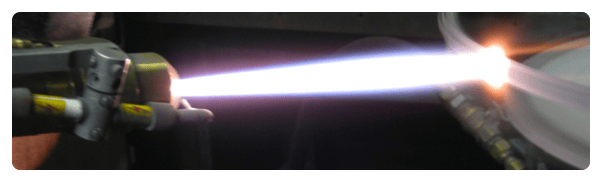

Carbide coatings are typically used for wear resistance to abrasion, erosion, galling, and fretting. Most “carbide” coatings are applied by HVOF to achieve the densest and most well-bonded coatings available by thermal spray.

Plasma sprayed carbide coatings may be selected to achieve a higher texture “as sprayed”. Some applications require flame spray applied coatings and a secondary fusing operation to provide a metallurgically bonded coating.

There are several different chemistries of “carbide” coatings including:

Types of Carbide Coatings

- Tungsten Carbide/Cobalt

- Tungsten Carbide/Nickel-Chrome

- Chrome Carbide/Nickel-Chrome

- Tungsten Carbide/Cobalt/Chromium

Carbide Coatings Resist:

- Fretting

- Sliding wear

- Erosion

- Abrasion

- Galling

- Some Impact

Benefits of Carbide Coatings

- High hardness, durability and toughness

- Abrasion and Erosion resistance

- Some Corrosion resistance

- Fretting Resistance

- Anti-galling properties

- Long Lasting Traction Surface

Carbide coatings are typically the most wear resistant coatings for abrasive wear.

| Type | Hardness | Properties | Examples of Uses |

|---|---|---|---|

| Tungsten Carbide/ Cobalt | Rc 60-65 | Wear resistance to Abrasion, fretting, galling | Conveyor screws, ball/gate valves, Impellers, particle classifiers |

| Tungsten Carbide/ Nickel- Chrome | Rc 53-58 | Resist wear by abrasive grains, hard surfaces, particle erosion/abrasion and fretting | Exhaust fans, sucker rod couplings, cylinder liners, cam followers |

| Chrome Carbide/ Nickel-Chrome | Rc 60-67 | Abrasive and fretting wear resistance at high temperatures | Turbine components, forging tools, hot forming dies |

| Tungsten Carbide/ Cobalt/ Chromium | Rc 60-70 | Wear and Corrosion resistance: Abrasion, erosion, & fretting | Pump components, hydraulic cylinders. Excellent material to replace hard chrome plating |

Typical Parts Coated with Carbide

- Rods

- Plungers

- Shafts

- Seal Areas

- Blades

- Impellers

- Rollers

- Guides

- Plates

- Discs

- Wheels